Pneumatics - Connections

Connections

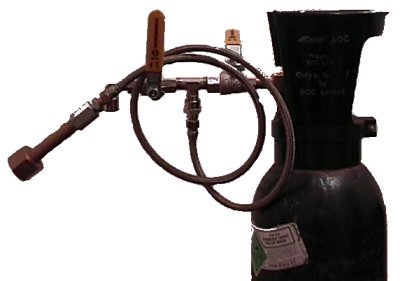

for the high pressure side of things - mostly the filling system - are

rather difficult to come by. The connections for the various types of gas

bottles are different to prevent the wrong gas being used for the wrong

purpose. In the case of CO2,

I tried everything to find out what the connection was. In the end, BOC

told me that because of the fact that CO2

is used in food and drinks machines, it is kept an industry secret to a

point. The connection is actually a right hand thread, 0.860" by 14 turns

per inch (TPI) male. So you need to get a nut and tube to fit this. I believe

that welding suppliers stock them, but I found the paintball industry was

the best place for the high pressure stuff. The tube in the picture is

an adapted paintball system decantor. The flexible hose is steel bound

and pin-pricked to prevent bubbles occuring and bursting the tube. The

connections at both ends are the same as both the CO2

bottle and the fire extinguisher we use have the same fitting. Go and talk

to a paintball supplier because they are much happier about dealing with

high pressure systems than BOC or Air Products.

Connections

for the high pressure side of things - mostly the filling system - are

rather difficult to come by. The connections for the various types of gas

bottles are different to prevent the wrong gas being used for the wrong

purpose. In the case of CO2,

I tried everything to find out what the connection was. In the end, BOC

told me that because of the fact that CO2

is used in food and drinks machines, it is kept an industry secret to a

point. The connection is actually a right hand thread, 0.860" by 14 turns

per inch (TPI) male. So you need to get a nut and tube to fit this. I believe

that welding suppliers stock them, but I found the paintball industry was

the best place for the high pressure stuff. The tube in the picture is

an adapted paintball system decantor. The flexible hose is steel bound

and pin-pricked to prevent bubbles occuring and bursting the tube. The

connections at both ends are the same as both the CO2

bottle and the fire extinguisher we use have the same fitting. Go and talk

to a paintball supplier because they are much happier about dealing with

high pressure systems than BOC or Air Products.

Also, hydraulic suppliers deal with high pressure equipment which can often be used with gas. They can make you a nice flexible, fast release filling system to your specification for around 80 or so UK pounds. Quick release connectors have the connector basically split into two self-sealing sections - a male and female part. This is commonly the way that robots are filled. Cassius, Chaos, Khz and Facet all use this filling system. It's very simple and quick to use. You fit the male nipple through the robots bodywork. When you need to fill up with gas, just put the female section (which is connected to the air supply by hose) over the male section. The connection allows the gas to flow only when fully connected.

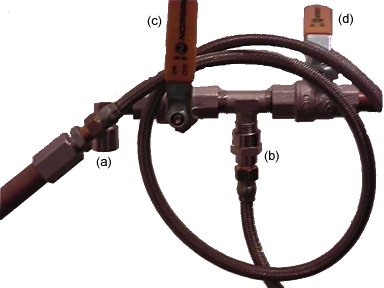

The

close-up picture shows the paintball system in more detail. (a)

is an exhaust port where the system can be depressurised. (b) is

the gas output to the flexible filling tube. This flexible tube connects

to your robot. (c) is the exhaust tap used to allow gas out through

(a).

(d) is the inlet tap which allows gas into the flexible tube. So,

a filling order would be:

The

close-up picture shows the paintball system in more detail. (a)

is an exhaust port where the system can be depressurised. (b) is

the gas output to the flexible filling tube. This flexible tube connects

to your robot. (c) is the exhaust tap used to allow gas out through

(a).

(d) is the inlet tap which allows gas into the flexible tube. So,

a filling order would be:

- (c) and (d) both shut.

- Connect flexible hose to robot.

- Open (d) to allow gas into robot.

- Close (d) when required amount is filled - made need a pressure gauge fitted too.

- Close valve on robot.

- Open (c) to exhaust excess gas through (a).

- Disconnect flexible tube. You are ready to go!

For connection of a completely high pressure system, such as those in Chaos or Cassius, hydraulic parts are needed almost entirely. Connections to and from the cylinders must be either high pressure, pin pricked hose, preferably steel banded or solid high pressure metal tubing at the correct pressure rating - similar to the tubes used for car brake systems. Connections between units will require either correct fitting screw fittings or welding (for metallic tube). If buying hydraulic hose, be aware that not all hose is suitable for all gases. Check the manufacturers data sheets and if still in doubt, ask a specialist. Our suggestion for high pressure systems is to get as much as possible made up by a hydraulics/pnuematics specialist. It costs a bit more, but they stuff will be tested for you at a much higher pressure. Paintball suppliers may also be of help.

One thing paintball people can help with is perfecting the Chill and Fill technique. With systems that use liquid CO2 it is important to get the holding tank as cold as possible when filling so that the liquid remains a liquid when transfered from one container to another. When liquid CO2 is exposed to warm air, the vapour starts to vent off back into its gaseous form. This will happen when you fill a warm container with liquid CO2 as well. This will mean you won't fill the tank properly. One side effect of venting CO2 is that is produces extreme cold as it rushes through from liquid to gas. This can be used to our advantage. First part fill the target tank with some CO2 - doesn't need to be a lot. Now vent this back out again as fast as possible. Feel the tank and you will notice it has got very cold. With practise, you can get the whole tank cold. You can now decant your liquid carbon dioxide and most of it will remain liquid. This is the chill and fill. It's not easy and takes practise to do it well. BTW, paintballers hang the target tank on some scales and weigh the amount of liquid going in. This is why you see 12oz tanks for sale. That is the weight of liquid it will hold when full.