CNC mill build thread

Moderators: BeligerAnt, petec, administrator

- peterwaller

- Posts: 3213

- Joined: Fri Feb 15, 2002 12:00 am

- Location: Aylesbury Bucks

- Contact:

-

Andrew_Hibberd

- Posts: 1134

- Joined: Tue Jan 20, 2004 12:00 am

- Location: London

- Contact:

Re: CNC mill build thread

After much sweat and blood and a few choice words the motors are mounted and the bed moving. The next thing on the list to do is to mount the control board and power supply inside the PC case. Still a lot to learn on the software and the I need to make a decision on how I am going to make the 4th axis. I hope to make my first cuts in the next few days.

TEAM GEEK!

-

Andrew_Hibberd

- Posts: 1134

- Joined: Tue Jan 20, 2004 12:00 am

- Location: London

- Contact:

ITS ALIVE...!!!!

I have extended the cables to the motors but all the electronics need sorting out this weekend as they are a bit of a mess. However I have got the machine cutting out its first bits from a plywood feather base I have had for a while.

I have been going through the CAM software that produces the tool paths for the machine, its got so many options its going to take a very long time to get the hang of. However I have made a short video to show it making a simple shape. I will try to make something more interesting over the weekend out of something harder.

http://www.youtube.com/watch?v=-S8X2MzxNf8

I have been going through the CAM software that produces the tool paths for the machine, its got so many options its going to take a very long time to get the hang of. However I have made a short video to show it making a simple shape. I will try to make something more interesting over the weekend out of something harder.

http://www.youtube.com/watch?v=-S8X2MzxNf8

TEAM GEEK!

- peterwaller

- Posts: 3213

- Joined: Fri Feb 15, 2002 12:00 am

- Location: Aylesbury Bucks

- Contact:

Re: CNC mill build thread

I know what you mean about the number of options on the CAM software I am afraid I tend to just work on tool paths.

Using a 2 mm mill for most or my machining I just generate a toolpath line 1 mm from where I want the edge.

For cutting out which is mostly what I do this is quite straight forward but it takes a lot to work out all the tool paths on large area removal.

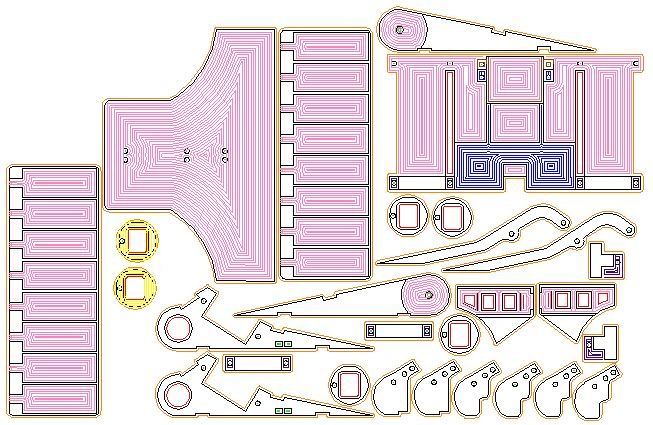

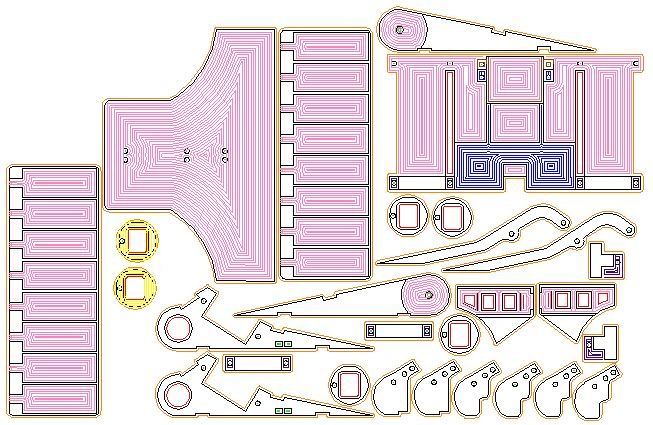

In the example the red it what I want and the black are the toolpaths.

Using a 2 mm mill for most or my machining I just generate a toolpath line 1 mm from where I want the edge.

For cutting out which is mostly what I do this is quite straight forward but it takes a lot to work out all the tool paths on large area removal.

In the example the red it what I want and the black are the toolpaths.

Re: CNC mill build thread

That is exactly how I work on the machine at school, using different coloured contours to define different final depths of cut and then setting these up accordingly with the output.

The black being the piece, orange a full cut and various other colours are the different depths.

The black being the piece, orange a full cut and various other colours are the different depths.

RPD International

www.RPDintl.com

www.RPDintl.com

-

Andrew_Hibberd

- Posts: 1134

- Joined: Tue Jan 20, 2004 12:00 am

- Location: London

- Contact:

Re: CNC mill build thread

The machine is all up and running. I can do anything up to Aluminum at the moment but am going to look at cutting steel in the future.

I am looking at selling CNC parts so feel free to PM me if you want something made and I will let you know the cost. Or if you require something from shapeways I can 3d design the part for you.

I am also looking at buying some of these Parker solenoid valves, but I need to buy them in bulk to save on the postage, would anyone be interested in one of these valves if I bought them?

http://www.parker.com/literature/Litera ... -valve.pdf

An old anticipation support from HDPE:

I am looking at selling CNC parts so feel free to PM me if you want something made and I will let you know the cost. Or if you require something from shapeways I can 3d design the part for you.

I am also looking at buying some of these Parker solenoid valves, but I need to buy them in bulk to save on the postage, would anyone be interested in one of these valves if I bought them?

http://www.parker.com/literature/Litera ... -valve.pdf

An old anticipation support from HDPE:

TEAM GEEK!

Re: CNC mill build thread

I might have another valve if you're going to order a few, did you get through to Parker?

RPD International

www.RPDintl.com

www.RPDintl.com

-

Andrew_Hibberd

- Posts: 1134

- Joined: Tue Jan 20, 2004 12:00 am

- Location: London

- Contact:

Re: CNC mill build thread

Hi Rhys

I am looking at selling them for £25 each, plus a little bit to post them as they are so light.

They take the same size tube as the robart equipment available from technobots. However for a lighter ram and better flip a lego ram could be modified to take the smaller pipe.

I am looking at selling them for £25 each, plus a little bit to post them as they are so light.

They take the same size tube as the robart equipment available from technobots. However for a lighter ram and better flip a lego ram could be modified to take the smaller pipe.

TEAM GEEK!

-

Andrew_Hibberd

- Posts: 1134

- Joined: Tue Jan 20, 2004 12:00 am

- Location: London

- Contact:

Re: CNC mill build thread

Its been a while since I last posted, I have been building a full pressure flipper using my milling machine. I will post pics when I have more done. However here is the 4th axis upgraded and turning:

http://www.youtube.com/watch?v=wt_a5_XdWJU

Also this is the machine cutting some HDPE like butter

http://www.youtube.com/watch?v=OCoZfast ... re=related

Look for some new silly robots in the next year.

http://www.youtube.com/watch?v=wt_a5_XdWJU

Also this is the machine cutting some HDPE like butter

http://www.youtube.com/watch?v=OCoZfast ... re=related

Look for some new silly robots in the next year.

TEAM GEEK!